Discover the possibilities and benefits of 3D Printed Jigs and Fixtures

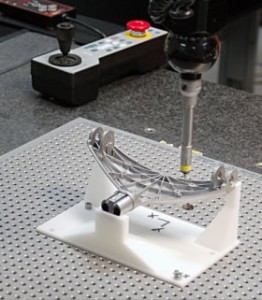

The answer lies in Jigs and Fixtures or more specifically, the revolutionizing of its production process through 3D Printing technology/Additive manufacturing. Traditionally, most Jigs and Fixtures are either manually fabricated or produced using machines. As a result, the production process is time consuming and costly, with some projects taking up to 3 weeks to complete if outsourced. However, this is all about to change with the use of 3D Printing technology.

Easy storage, enhanced ability to make revisions and a smooth work process are just some of the benefits that 3D Printing Jigs and Fixtures can bring. In addition, designs can also be easily altered and improved to increase the overall effectiveness of the jigs and fixtures.

Another advantage of 3D Printing Jigs and Fixtures is the decreased production time and cost. Experience up to 40-90% lead time reduction and 70-95% cost reduction with additive manufacturing and create a positive impact on your company’s bottom line.

Greater returns, time savings and productivity- all at once- sounds too good to be true? Fret not, as this is entirely achievable by integrating 3D printing into the manufacturing process. To find out more about the possibilities and benefits of 3D Printing Jigs and Fixtures and what it can do for your business, click here to download the white paper.

As a service and solutions provider, Creatz3D Pte Ltd specializes in distributing 3D printing technologies and rapid prototyping solutions in Singapore, Indonesia and Vietnam. We are the authorized reseller for Stratasys™ 3D printing systems and materials, Arcam™ additive manufacturing solutions for metal components’ production as well as Materialise™ Rapid Prototyping & Biomedical Engineering Software.

For more information, you can choose to contact us via email at info@creatz3d.com or 6631 8555.